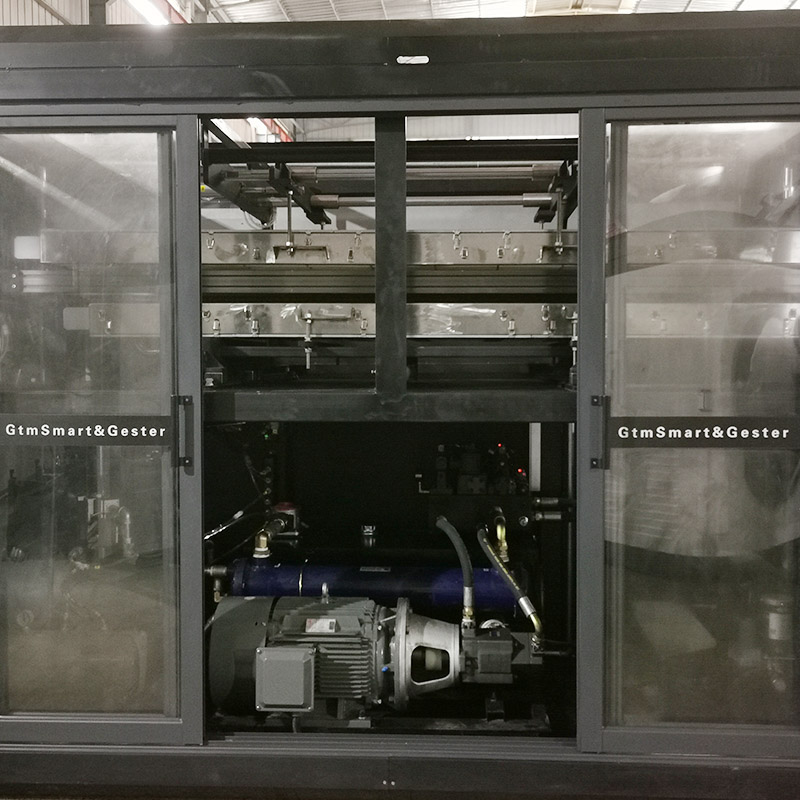

Automatic Disposable Plastic Glass Making Machine Cup Thermoforming Machine

Cup Making Machine Introduction

Plastic glass cup making machine is suitable for molding PP, PET, PS, PLA and other plastic sheets to produce various packaging products such as boxes, plates, cups, bowls, lids, etc. Such as: milk cups, jelly cups, ice cream cups, drink cups, food bowl, etc.

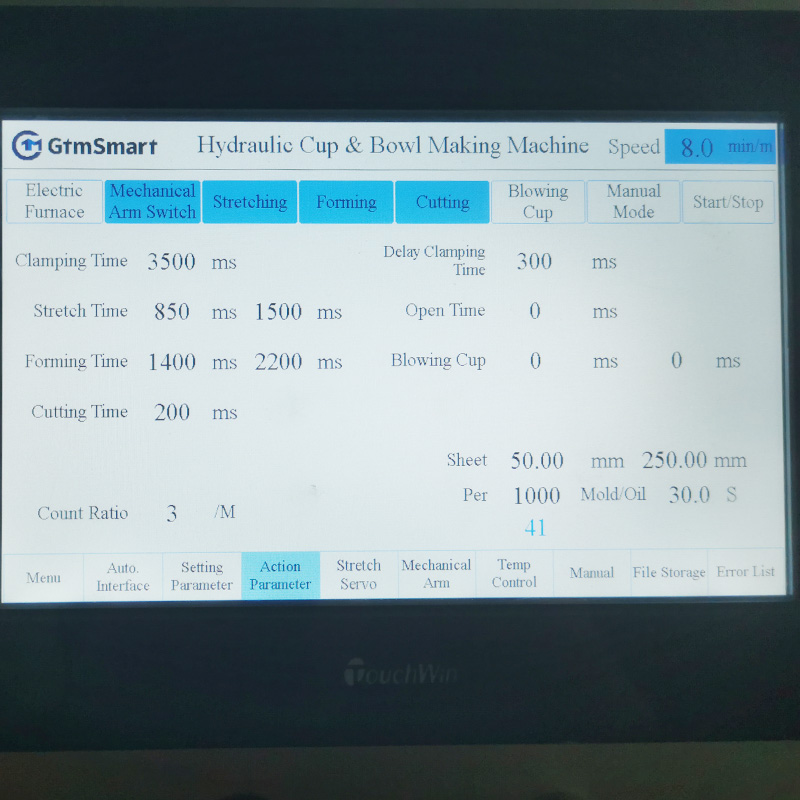

Cup Making Machine Specifications

| Model |

HEY11-6835 |

HEY11-7842 |

| Max.Forming Area (mm2) |

680*350 |

780x420 |

| Working Station |

Forming, Cutting, Stacking |

|

| Applicable Material |

PS, PET, HIPS, PP, PLA, etc |

|

| Sheet Width (mm) | 350-810 | |

| Sheet Thickness (mm) | 0.3-2.0 | |

| Max. Forming Depth (mm) | 180 | |

| Max. Dia. Of Sheet Roll (mm) | 800 | |

| Mould Stroke(mm) | 250 | |

| Length of upper heater (mm) | 3010 | |

| Length of lower heater (mm) | 2760 | |

| Max. Mold Closing Force (T) | 50 | |

| Speed (cycle/min) | Max 25 | |

| Accuracy of Sheet Transport(mm) | 0.15 | |

| Power Supply | 380V 50Hz 3 phase 4 wire | |

| Heating Power (kw) | 135 | |

| Total Power (kw) | 165 | |

| Machine Dimension (mm) | 5290*2100*3480 | |

| Sheet Carrier Dimension (mm) | 2100*1800*1550 | |

| Weight of Whole Machine (T) | 9.5 | |

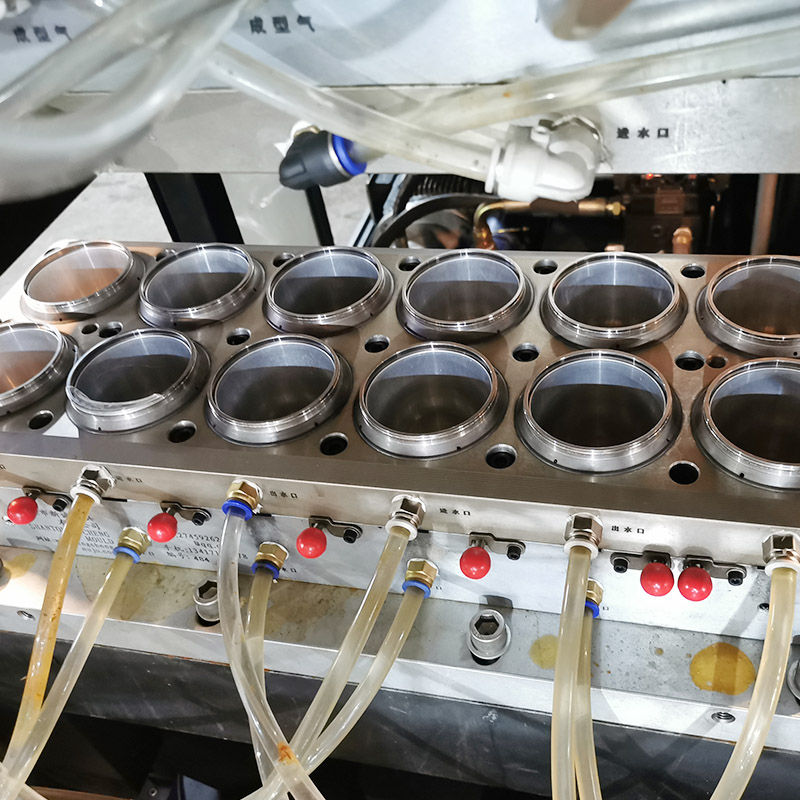

plastic cup making machine Feature

1.Auto-unwinding rack:

Disposable plastic cup making machine designed for overweight material by using pneumatic structure. Double feeding rods are convenient for conveying materials, which not only improves the efficiency but reduces the material waste.

2.Heating:

Plastic glass making machine upper and down heating furnace, can move horizontally and vertically to ensure that the temperature of the plastic sheet is uniform during the production process. Sheet feeding is controlled by servo motor and the deviation is less than 0.01mm. The feeding rail is controlled by closed-loop waterway to reduce the material waste and cooling.

3.Mechanical arm:

Plastic cup forming machine can automatically match the molding speed. The speed is adjustable according to different products. Different parameters can be set. Such as picking position, unloading position, stacking quantity, stacking height and so on.

4.Waste winding device:

Plastic Cup Thermoforming Machine adopts automatic take-up to collect surplus material into a roll for collection. Double cylinder structure makes the operation easy and convenient. The outer cylinder is easy to take down when the surplus material reach a certain diameter, and the inner cylinder is working at the same time. This plastic glass machine operation will not interrupt the production process.

Send your message to us:

Products Recommended

More +-

Model: HEY12

Model: HEY12Full Servo Plastic Cup Making Machine HEY12

Full Servo Plastic Cup Making Machine cup making machine Application The cup making machine is Mainly for the production of variety plastic containers ( jelly cups, drink cups, package containers,... -

Model: HEY11

Model: HEY11Hydraulic Servo Plastic Cup Thermoforming Machine HEY11

Hydraulic Servo Plastic Cup Thermoforming Machine HEY11 Cup Thermoforming Machine Application The whole Plastic Cup Thermoforming Machine Mainly for the production of variety plastic containers (... -

Model: HEY02

Model: HEY02Four Stations Large PP Plastic Thermoforming Machine HEY02

Product Introduction Four Stations Large Plastic Thermoforming Machine Mainly for the production of variety plastic containers ( egg tray, fruit container, food container, package containers, etc)... -

Model: HEY12

Model: HEY12Biodegradable PLA Disposable Plastic Cup Making Machine

PLA Biodegradable Disposable Plastic Cup Making Machine Application Biodegradable cup making machine mainly for the production of variety plastic containers ( jelly cups, drink cups, pa... -

Model: HEY01

Model: HEY01PLA Degradable Compostable Plastic Lunch Box Plate Bowl Tray Thermoforming Machine

Thermoforming Machine Key Specification Model HEY01-6040 HEY01-7860 Max.Forming Area (mm2) 600×400 780×600 Working Station Forming, Cutting, Stacking Applicable ... -

Model: HEY05

Model: HEY05Plastic Vacuum Forming Machine HEY05

Vacuum Thermoforming Machine Description Vacuum forming, also known as thermoforming, vacuum pressure forming or vacuum molding, is a procedure in which a sheet of heated plastic material is shape... -

Model: HEY27

Model: HEY27Mechanical Arm HEY27

Application This manipulator has the characteristics of high speed, high efficiency and stability through product optimization design. In order to improve the production of the original suction mol... -

Model: HEY14

Model: HEY14Rim Roller HEY14

Features 1.Integrated design, optical fiber cup, high efficiency, low energy consumption. 2.Give consideration to two functions of curling and counting. 3.Edge screw is made of copper, which is mor... -

Model:

Model:Biodegradable PLA Lids

MOQ: 10000 pcs PLA Biodegradable Factory direct sale Environmentally friendly Lids sold separately. Customizable Compostable PLA cup lids fits on 9, 12, 16, 20 and 24 oz cups. PLA bio-plastic mad... -

Model:

Model:Biodegradable Plastic Sauce Containers Cups

Industry-specific attributes Product Biodegradable plastic sauce containers Material PLA Industrial Use Food MOQ 5000 pcs Size 3.25oz, 4oz, 5.5oz Biodegradable sauce container... -

Model:

Model:PLA Plastic Disposable Clear Cold Drinking Juice Bubble Tea Ice Coffee Cups

Introducing our new range of biodegradable cup, the perfect eco-friendly solution for all your beverage needs. Made from plant-based materials, these cups are not only eco-friendly, but also durabl... -

Model:

Model:PLA Disposable Compostable Biodegradable Plastic Ice cream/Soup/Tasting Spoons

Product parameters Product Name Biodegradable Spoon Material PLA Size 6.3in, 16cm MOQ 10000 pcs Advantages Factory direct sale, eco friendly, compostable Product Description ...